Milk Plants

New demands and changing circumstances in the safe, responsible, cost-effective production and processing of milk do continuously invoke the development of new analytical approaches. Robust, versatile and affordable rapid methods facilitating measurement and automating data collection are popping up at hot spots throughout the dairy supply chain!

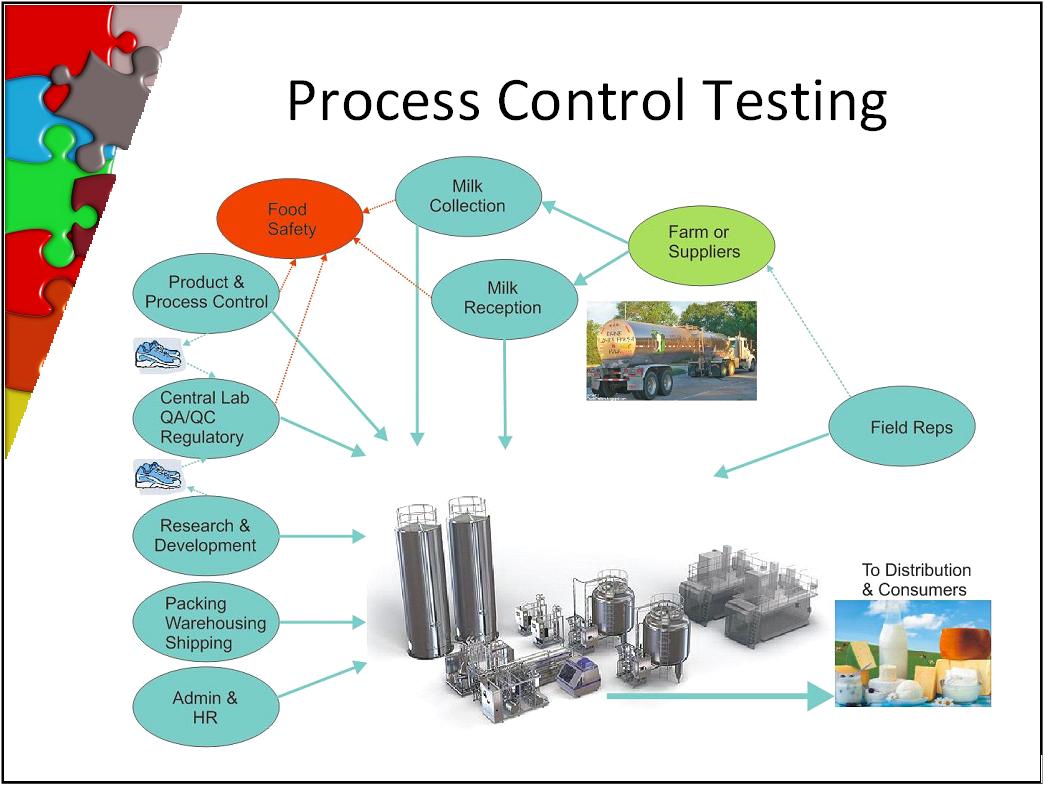

Taking control and keeping control of the system is of paramount importance. In evaluating critical control points in a dairy processing plant (of any size or shape), focus is on Milk Collection/Milk Reception, Product and Process Control. The following illustrates key control points in any processing system:

The LactiCheck Milk Analyzer is a compact and robust milk composition analyzer that can provide a comprehensive analysis (fat, solids, density, added water, lactose and protein) in just seconds at any point in the plant! Suitable for Milk Reception, satellite locations on or around the Production Floor and in R&D, the LactiCheck provides impressive value and flexibility to small, medium and large dairy processing plants!

The QuickCheck TECH freezing-point cryoscope provides an impressively accurate assessment of added (or extraneous) water in milk in accordance with internationally reviewed and recommended methods for payment purposes. It is an essential tool in Milk Reception and also helpful in confirming proper process functionality throughout the plant.

The P2MA-50 Halogen Infrared Moisture Analyzer gives critical insight into total moisture content of value added products (i.e. cheese, yogurt). This information contributes to proper packaging decisions as well as safe shelf-life parameters.

Optimizing outcomes through proper monitoring of safety and suitability for manufacture into value-added products, satisfactory shelf-life potential, etc.) ensures consistent performance and reliability in these areas. Reflect upon how to improve the process control you have in place to enhance productivity, reduce waste, save energy and optimize quality and profitability.